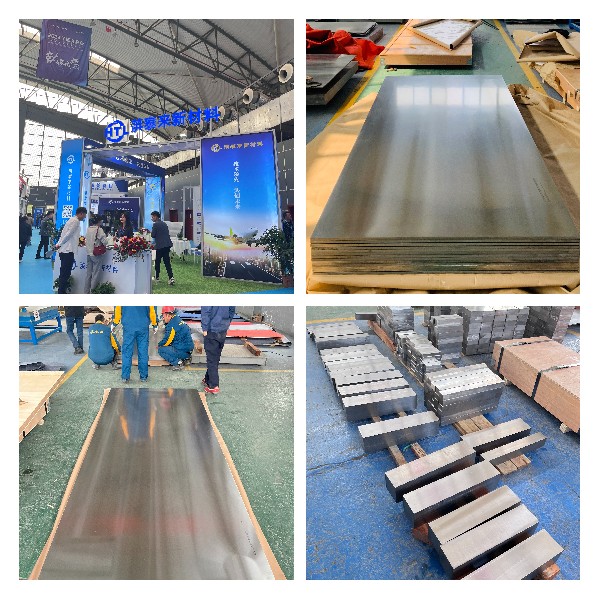

Recently, Shaanxi Hongtailai New Materials Co., Ltd. ,successfully rolled titanium plates, high-value-added products for export, at its refining and rolling plant. This achievement fulfilled the processing orders and further expanded the channels for cost reduction and efficiency improvement, enhancing profitability.

Titanium plates are known for their high strength, strong corrosion resistance, and light weight. They exhibit excellent corrosion resistance and stability in seawater, making them preferred materials for offshore oil and gas exploration. They are also used in aerospace, nuclear, and chemical industries, offering significant development potential and broad application prospects.

However, due to the specialized nature of titanium plate processing and the characteristics of small-batch production in high-precision fields, there are very few domestic companies dedicated to titanium plate processing.

In recent years, in order to expand innovative and efficient channels, HTL’s refining and rolling plant has ventured into the processing business of titanium plates and has become a domestic enterprise capable of processing them into finished products. The plant has received high recognition from customers for its rolling capacity and quality. In this particular case, the customer proactively contacted the plant, requesting HTL’s processing and rolling of titanium plates. The order is big, and the delivery time is tight. The plates will be used in a foreign maritime project.

According to Mr.gao, the chief technician for medium-thick plate rolling at the plant, titanium plate rolling has specific characteristics such as low heating temperature and rapid cooling. Typically, the rolling temperature for steel is around 1200°C, while for titanium plates, it needs to be controlled below 850°C. The process control requirements are high, and the temperature changes have a significant impact on the production line. Other domestic steel mills use a “two-heating” process to produce finished products, but the refining and rolling plant has achieved “single-heating” rolling through technological exploration, significantly reducing the delivery cycle.

This year, the plant has made comprehensive arrangements in terms of heating effects and plate rolling profiles, further optimizing the equipment maintenance plan. While achieving continuous casting, they have shortened the time previously consumed in rolling titanium plates by 5 hours, effectively improving the rolling operation rate. Additionally, through technological and process innovations, the plant has increased the yield of processed titanium plates, reducing production costs and playing a role in expanding channels for high-value-added product orders.

It is worth mentioning that through coordinated development of production lines, the refining and rolling plant has acquired the one-stop service capability for processing titanium plates at HTL, greatly enhancing its capacity to undertake titanium plate contracts. This has strengthened the overall processing capabilities of the company and played an important role in winning customers and maintaining stable channels for efficiency gains.