Titanium and titanium alloys not only have high melting points, non-magnetic properties, low thermal expansion coefficients, high specific strength (strength-to-density ratio), and high specific stiffness (elastic modulus-to-density ratio), but also possess many excellent characteristics such as good corrosion resistance and resistance to biological erosion.

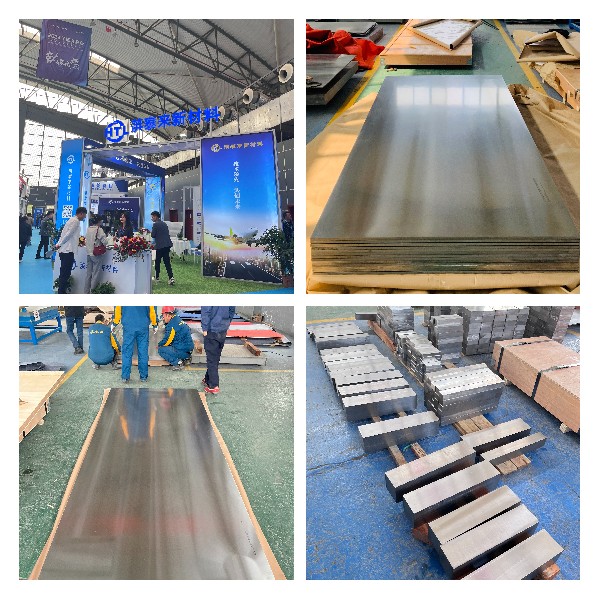

TA9(Ti-0.2Pd) alloy is mainly used in environments with dilute hydrochloric acid, dilute sulfuric acid, and dilute phosphoric acid. It is also widely used in titanium equipment to prevent crevice corrosion, such as in tube-and-shell heat exchangers and components for textile spray heads. TA9(Ti-0.2Pd) titanium alloy, as an alloy formed by adding a small amount of precious metal Pd to pure titanium, exhibits excellent corrosion resistance in acidic media. The presence of non-toxic alloying elements Al and V makes it a high-quality material that can replace pure titanium and Ti-6Al-4V for biomedical implants. High-strength titanium alloy plates, such as TA9(Ti-0.2Pd) high-temperature resistant titanium plates, have a density of approximately 4.51 g/cm³, which is only 60% of that of steel. The strength of pure titanium is comparable to that of ordinary steel, and some high-strength titanium alloys surpass the strength of many alloy structural steels.

Therefore, the specific strength (strength/density) of titanium alloys is much higher than that of other metal structural materials, as shown in Table 7-1, making it possible to produce lightweight components with high strength and good rigidity. Currently, titanium alloys are used in aircraft engine components, frameworks, skins, fasteners, and landing gears.

The main mechanical properties at room temperature are as follows:

- Tensile strength Rm (σb): 1000 MPa

- Elongation A5: 10%

- Impact toughness Ak: 20-30 J/cm²

TA9(Ti-0.2Pd) titanium-palladium alloy is characterized by its lightweight, high strength, good biocompatibility, and excellent corrosion resistance. It is widely used in the chemical, petroleum, and food industries, and has expanded to aerospace and biomedical fields.

The characteristic of TA9(Ti-0.2Pd) titanium alloy is that it cannot be strengthened through heat treatment and is typically used in an annealed state. It exhibits good thermal stability, high thermal strength, and excellent weldability. Various welding methods can be employed under inert gas protection. However, it has lower strength at room temperature and, being an α-type titanium alloy, it has a hexagonal crystal structure with fewer slip systems during plastic deformation, resulting in poorer plastic deformation capability compared to other types of titanium alloys. It can withstand long-term operation at 500°C and can be used in the manufacturing of components such as engine compressor discs and blades.